WebStamp September 16, 2020

Building Better Eco-Friendly Homes

Even though there have been many new building materials introduced in the last century to help reduce the costs of building a house, the savings usually outweigh the durability. Calgary recently discovered that inexpensive vinyl siding does not stand up to severe weather conditions. Many homes in the far north-east had destructively been damaged by hail breaking windows and damaging roofs and cheap siding. The community of Saddle Ridge, which was hit the hardest, has the Ward 5 Councillor George Chahal advocating the province to rebuild these homes with more sustainable or resilient building options.

Vinyl siding, the most widely cladding because of lower building costs, is basically a plastic exterior siding that usually is quite durable but not indestructible. It can be severely damaged with massive hail storms, melts in a fire, and can become brittle in extreme cold. There are other more durable materials available which are usually more expensive. Alternative sidings include aluminum, wood, fibre cement, brick and stone with the latter three being the most durable and fire-resistant.

Many new eco-friendly building products are being developed, however, only those items made from industrial hemp (not marijuana) are both eco-friendly and carbon neutral. Hemp Board is made with non-toxic bio-products and is predicted to replace MDF and particleboard. Hemp Board is a lighter, stronger, water and mould resistant, and flame-retardant panel that also has excellent insulating properties.

Since everything that can be made from plastic can be made from hemp why has no one started producing hemp siding? Hemp plastic can be 5 times stiffer and 2.5 times stronger than polypropylene plastic (PP). With already over 23000 acres of industrial hemp grown in Alberta, we could easily create a Local Circular Economy producing economical hemp siding as an alternative to vinyl siding.

There are also many other materials used in the building industry that are not eco-friendly and use toxic substances. Fibreglass is the most widely used insulating material and even though it is mostly made from sand and glass they do use formaldehyde as a binder that can leak out into the home. It also tends to lose its R-value over time and needs to be kept dry to prevent mould. Hemp insulation would be a better substitute for it has a greater fire-resistance, is breathable, and has a greater R-value.

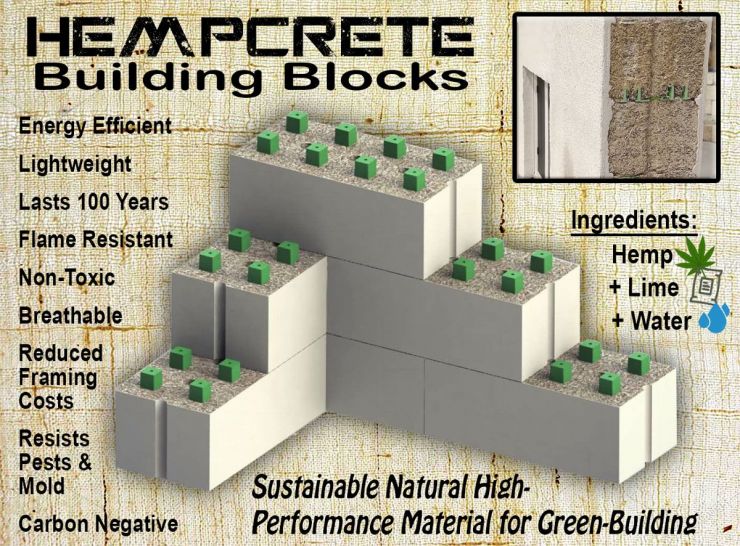

Hempcrete, a form of concrete made from hemp hurd, is stronger and more durable than concrete. It does take a long time to cure so it does require an inner structure for support. To solving the vertical load-bearing compression strength problem there is a company in Airdrie, AB. that manufactures the Just BioFiber Block made from hempcrete with an internal structural composite frame.

Industrial hemp can be made into many high-performance, low-carbon, natural, petroleum-free quality building products. Hemp building products are carbon-neutral and help cleans the air by absorbing large amounts of CO2 from our atmosphere during its lifetime. It can also be used to replace many other toxic products currently used in our homes. Hemp products can be made into non-toxic versions of oils (in paints and other products), and replace many types of fabrics, carpets, and items that release flame-retardants and harmful VOCs into our homes.

There are many options available for building structures. We need to stop building homes with products that are harmful, in the way these products are made, and the environment we live in.

The elimination of the Sick Building Syndrome is possible but only if we rethink how our buildings are made and how they can be made better and healthier.

Articles in this Issue

WebStamp September 16, 2020

References: